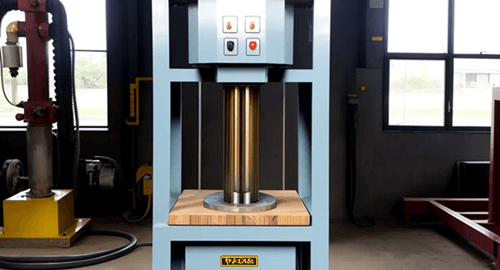

Deep drawing hydraulic presses have been a cornerstone in the manufacturing industry for producing metal components. This method involves radially drawing a sheet metal blank into a forming die by the mechanical action of a punch. As with any machinery, there are ways to optimize the process for maximum efficiency and precision. Below are five best hacks users can employ for optimal results.

Prevent Wrinkling with a Blank Holder:

One of the most common issues during deep drawing is the wrinkling of the sheet. By using a blank holder, you can apply a force that opposes the drawing force, holding the metal sheet firmly in place. This prevents the formation of wrinkles and ensures a smooth finished product. It also improves the overall quality of the finished products.

Lubrication is Key:

Friction can be a real challenge in deep drawing. Ensure you select the right lubricant for the material you are working with. Lubrication not only reduces wear on your tools but also minimizes tearing and scratching on the metal piece. Whether you’re using oil, wax, or a specialized lubricant, even application can make all the difference in the finished product’s quality.

Material Matters:

Always ensure you’re using the appropriate material for your desired product. Metals such as stainless steel, aluminum, and brass each have unique properties, and knowing their malleability and tensile strengths will help ensure the desired depth and finish in the final product. Regularly inspect the metal sheets for any signs of defects or imperfections that might affect the drawing process.

Monitor Press Speed and Pressure:

Operating at the right speed and pressure is crucial for the consistency of the products. Too much speed can lead to tearing, while too much pressure might cause the metal to thin out excessively or even rupture. By constantly monitoring and adjusting, users can ensure they’re getting the best results possible every time.

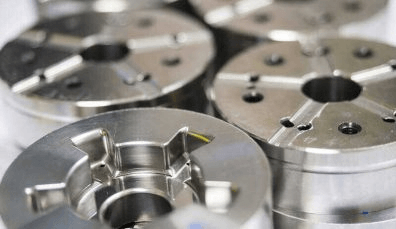

Regular Maintenance and Calibration:

A well-maintained hydraulic press will always deliver better results. Make it a routine to check for wear and tear, especially on the punch and die, as these are the components that undergo the most stress. Calibrate the machinery regularly to ensure consistent results, and replace worn-out parts as needed to keep the press operating at its best.

Looking for the best deep drawing press machine, click it here.